Why Choose us.

Quality Mold Starts from

Excellent Design

The performance of a tool largely depends on the maturity of its design. The many years of experience of our designers is therefore a decisive factor with regard to the quality of Huaview mold.

We collaborate closely with our customers on all aspects of the programs so as to develop the best designed molds that are easy to maintain, and plastic components that are cost-effective to produce.

Our skilled in-house design team have over 15 years experience in designing custom tooling. We offer full design package:

Feasibility studies and design recommendations

Filling simulation & Moldflow analyse

Tool design 2D & 3D (CAD, Unigraphics, and others...)

If needed, our designers can involve in very early stage of a project, to support you during the part development, in order to enable a tool-specific design, thus to save your time and costs.

Manufacture

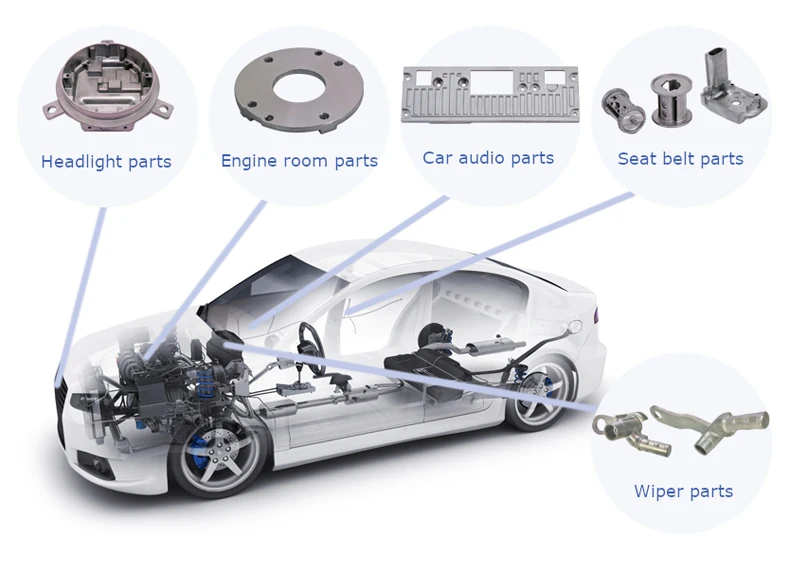

With tooling shop possessing different machines and expertise, we can offer tools from small precise parts to big complex automotive parts.

With our leading technology, quality and project management, we have pioneered international cooperation with world-famous automotive OEMs and Tier-1 companies, and achieved fruitful results.

We sell not only molds, but also technical support, efficiency, speed and quality.

Quality control:

our entire manufacturing process is covered by quality standards of ISO 9001.

Quality is crucial to everything we do at ASM, from design through to mold-making, engineering, injection molding and part assembly.

we have a dedicated Quality Department to ensure delivering quality molds and molded parts that we manufacture to meet and exceed our customers exacting needs and specifications.

Project management

Professional project management in tool making means much more than monitoring milestones.

In order to guide your project through the individual processes, an experienced project management team is available to you in our company.

We attach particular importance to the systematic management, various documentation and check lists, in order to control each process and thus creates a continuous and reliable performance of each project.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!