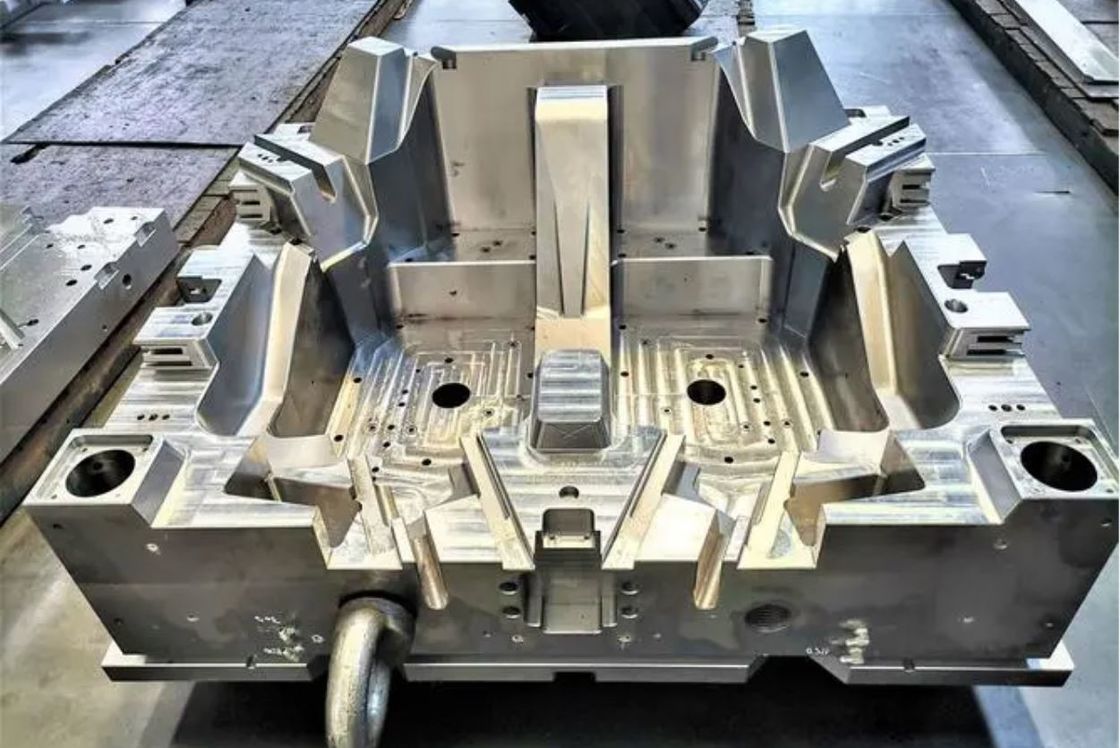

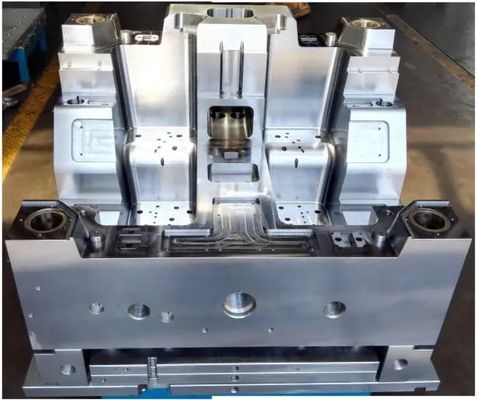

Big Size Mold Base For Large Scale Injection Mold Base Made Of P20 Steel

big size mold base for large scale injection mold

Specifications

| Mold Base Type |

CI, DI,FCI,DCI,……all is available |

Additional machining |

Water line, rough machining |

| Material |

P20,S50C,NAK80,S136……… |

Outside of mold base |

Granding |

| Life shots |

1,000,000 shots |

Accessory Part |

DME,HASCO,LKM standard |

| File format |

X-T, STP, IGS, Solidwork |

Customer customization |

available |

| Unit of Dimension |

MM, or INCH |

Crane Thread |

Metric, or English |

| Hot runner need |

Yes |

Packing |

wooden case packing |

Features:

Material: The mold base is made of P20 material, known for its excellent machinability and good polishability.

Standard: It follows the HASCO EQV standard, ensuring compatibility and ease of use with various mold components.

Industrial Application: The mold base is designed for automotive applications, specifically for car lamps.

Mirror Polishing: The mold base undergoes a mirror polishing process, resulting in a smooth and highly reflective surface finish.

Mold Base Types: It is available in various types such as CI, DI, FCI, DCI, etc., catering to different molding requirements.

Additional Machining: The mold base can be further machined to incorporate features like drill water lines and rough machining as per specific needs.

Longevity: The mold base has a life cycle of up to 1,000,000 shots, ensuring durability and prolonged usability.

Accessory Parts: It is compatible with accessory parts from reputable brands like DME, HASCO, and LKM.

File Formats: Acceptable CAD file formats include X-T, STP, IGS, and Solidworks, facilitating seamless communication with design teams.

Packaging: The mold base is vacuumized and packed in a wooden case to ensure safe transportation.

Applications:

We supply mold base to the automotive mold maker worldwide.

Valve add service.

- Can be do mold design for customer.

- Assist customer to order standard part, such as ejector pin core pin, water line plug, machine mold insert.

- Machining the cavity pocket, or core from A/B sold of moldbase.

Questionary

- How to order?

Please send me the drawing and require, and then we make offer the most competitive price, and deliver the moldbase after finished.

- How to maintain the quality?

A side plate and B side plate are machine by same machine, the can maintain the guide pin and bush are in same position, We do fully inspection before shipment, we can rework a new plate if dimension is reject.

- What’s the CAD file format?

X-T, STP, format is fine for us.

- How about the shipment?

We can handle the shipment by our company, we can deal with EXW, FOB, CIF and DAP term.

- How about the lead time?

For the size below 500mm, the lead time is 5-10days, for the size from 600-1200mm the lead time will be 10-15 days, for the size over 1500mm, the lead time will be about 15-20days.

But we can put you work in top priority if you order are very urgent. Lead time can be adjustable.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!